Spooling machines for sale or rental

Do you want to replace the wire rope of your crane with a new one or re-spool an existing rope? We have the solution for that too! We offer you a selection of rope winding machines in various designs, exactly suited to your needs.

As a crane owner – whether it is a mobile crane, crawler crane or ship crane – you will certainly have to replace or at least rewind the wire rope from time to time. You can buy the spooling machines directly from the manufacturer or rent them if you only need this rope winding machine sporadically.

Constant tension:

The constant tension (CT) ensures that the wire rope is wound up evenly and under the same force, regardless of the rope position / layer on the drum. This applies to both winding and unwinding the rope.Data-Logging-System:

The data logging system archives all data from each winding process, allowing you to compare values retrospectively, provide documentation to your customers, or optimize processes for the future.Easy transport and assembly:

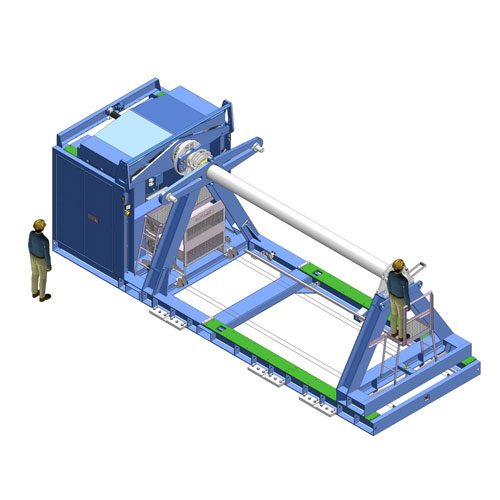

Easy transport and assembly is ensured thanks to the frame on which the machine is mounted. This is provided with forklift pockets and various attachment points. Larger spooling machines are also based on standard container dimensions, such as 10 ft or 20 ft containers, which avoids additional costs for special transport.

In addition, the spooling machine can just as easily be used the other way around, i.e. for unwinding the ropes from the crane onto a reel. To do this, the CT is adjusted, the wire rope is tightened and then lowered from the crane piece by piece.

Here you will get a rough overview of the technical properties and the diverse application possibilities. If you need more information, we will be happy to advise you.

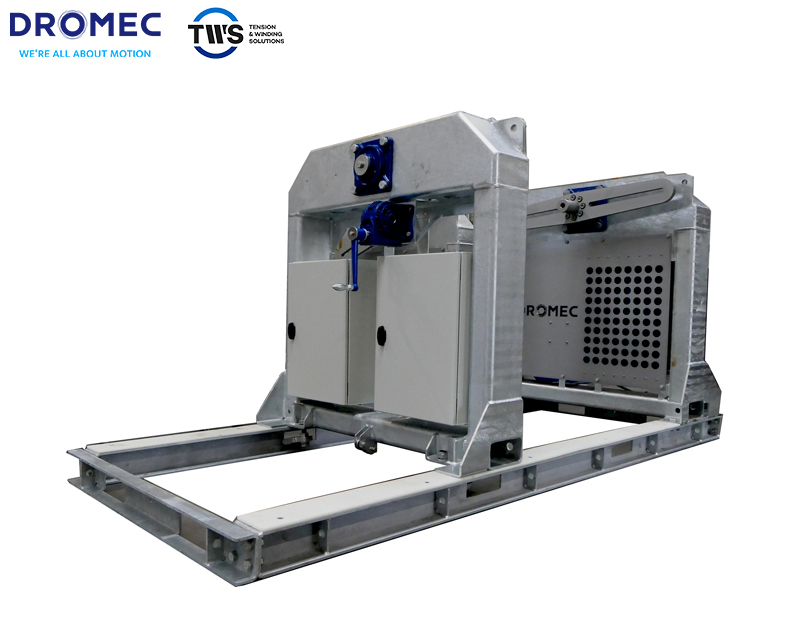

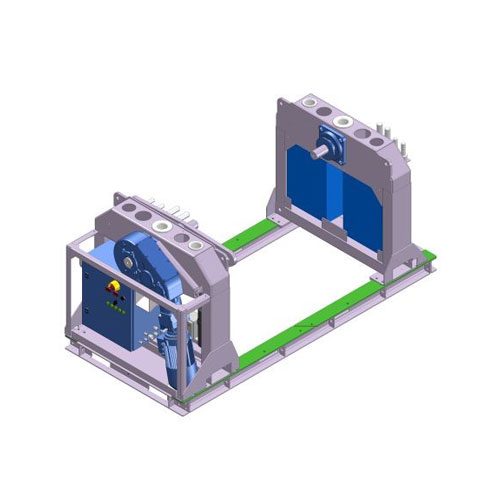

Example of a spooling machine

Applications for spooling machines

There are numerous applications for rope winding machines, such as:

Features of the spooling machine

The features of the rope spooling machine are as follows:

- Reel weight: up to 250 t possible

- Power supply: 400 V 50 Hz 3 Ph or 440 V 60 Hz 3 Ph

- Remote control: high-end remote control enables easy control via touchscreen and a permanent data overview

- A constant tension is possible in both directions

- Option for manual winding and unwinding of the rope

- Adjustable maximum speed

- Adjustable maximum torque

- Data logging system: archiving of all project data

- Optical sensors: always ensure the precise execution of the settings

- Simple and movable adapters: ensure precise anchoring of the reel

- Suitable for various axles or axle stubs

- Additional rope guide possible for larger models

Model examples

Here you will find an overview of model examples of spooling machines and corresponding accessories:

Small standard spooling machine

Very tall spooling machine

Operating a rope winding machine

Touch screen operation