MULTI-LUG LIFTING BEAMS

The robust and versatile lifting solution

Price on request!

The robust and versatile lifting solution

Price on request!

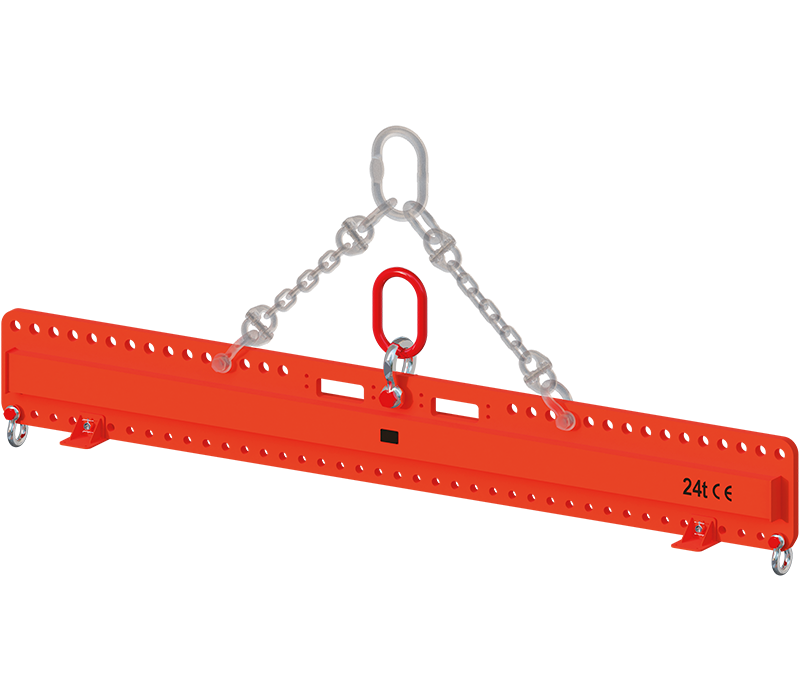

The multi lug beams from OX & RUD Lifting Solutions are extremely robust and versatile. This perforated lifting beam offers numerous attachement points at regular intervals and can therefore be adapted to different lifting operations.

On the top side it is possible to use the multi lug beam with a central shackle (as a lifting beam), but alternatively also with a 2-leg suspension (i.e. as a spreader beam or a semi-spreader; please always take the sling angles into account). Regardless of which configuration is used, the load capacity always remains the same.

This combination of possible uses offers enormous flexibility.

The multi-lug-beams with load capacities of 10 t, 24 t, 34 t and 50 t and a span of 4 m are normally in stock either in Germany or at the manufacturer in Spain, so that short-term delivery is also possible. (Subject to prior sale).

Advantages of multi lug beams from OX & RUD Lifting Solutions are as follows:

You can use the multi lug beams flexibly as a lifting beam, a spreader beam or a semi-spreader, depending on what your next lifting operation requires.

Thanks to their design, the multi lug beams offer a robust and versatile solution for many lifting operations.

The multi lug beams have a very good price-performance ratio.

These kind of lifting beams are usually in stock with load capacities of 10 t, 24 t, 34 t and 50 t and a span of 4 m either in Germany or at the manufacturer in Spain, so that short-term delivery is also possible.

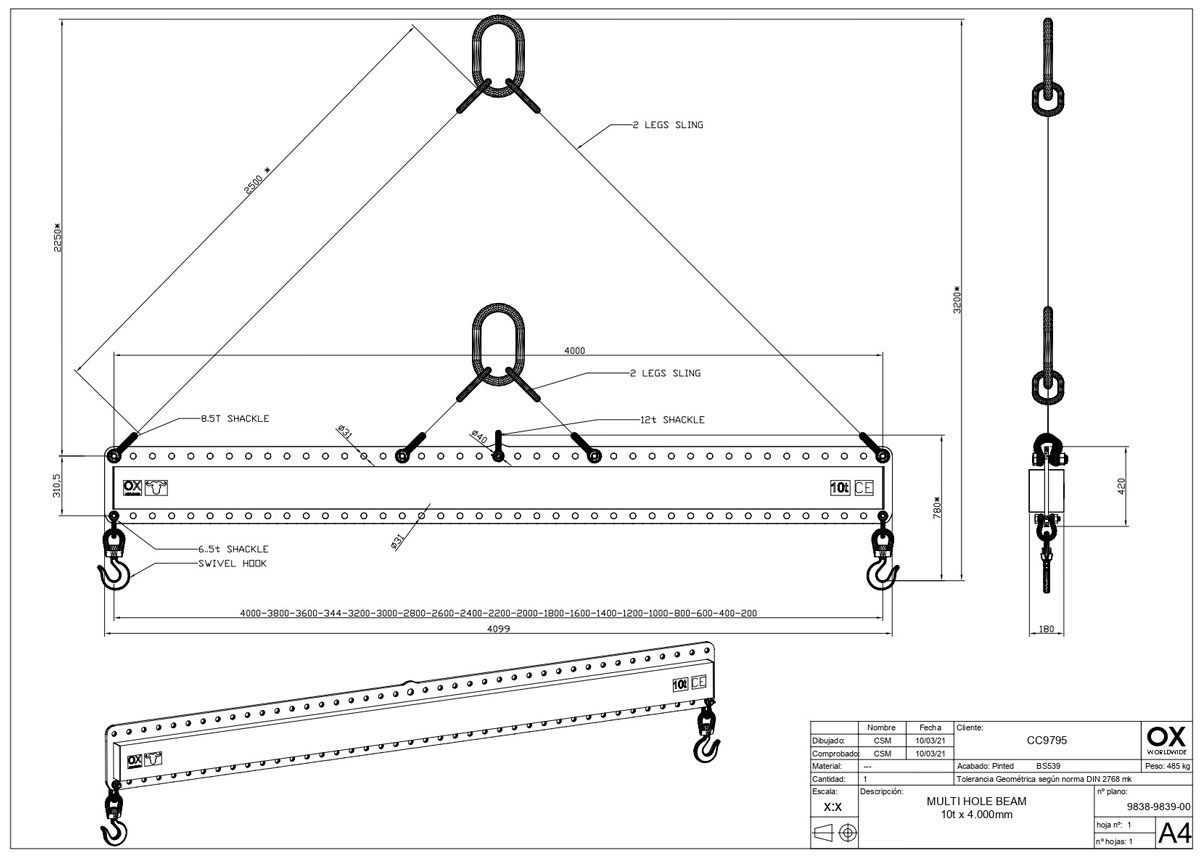

The drawing below shows various possible uses of the multi lug beam from OX & RUD Lifting Solutions.

Example of possible applications for a 10t multi hole beam from OX & RUD Lifting Solutions

Material:

Structural steel and steel with a high elastic limit are used to manufacture the lifting beams. These are optionally available with a 3.1. Material certificate.

Finish:

The company OX & RUD Lifting Solutions is ISO 9001:2015 and ISO 3834-2 certified. The following guidelines are used for design and production:

Here you will find examples from the product range of OX & RUD Lifting Solutions. This currently includes four versions with load capacities of 10 t, 24 t, 34 t and 50 t. The length of the models is 2 m or 4 m. We recommend the use of multi lug container beams especially for container handling.

We would be happy to provide you with a complete offer for the multi lug beams. Just ask us about suitable shackles and slings!

We will make you an offer,

for free & without obligation.

Dear visitors,

It is very important to us that you can use our website to its full extent and that you can quickly find the information you want about us and our products. Please agree to the use of cookies so that we can provide you with the best possible service based on your data. Of course, you can withdraw your consent at any time under "Settings" or adjust your details.

We may request cookies to be set on your device. We use cookies to let us know when you visit our websites, how you interact with us, enhance your user experience and customize your relationship with our website.

Click on the different category headings to find out more. You can also change some of your preferences. Note that blocking some types of cookies may impact your experience on our websites and the services we are able to offer.

These cookies are strictly necessary to provide you with the services and features available on our website.

Because these cookies are strictly necessary to provide you with the services and features available on our website, rejecting them will impact how our website works. You can block or delete cookies at any time by changing your browser settings and force blocking all cookies on this website. However, you will always be asked to accept/reject cookies when you return to our website.

We fully respect your wish to reject cookies. To avoid being asked for cookies again and again, please allow us to store a cookie for your preferences. You can opt out at any time or allow other cookies to fully use our services. If you reject cookies, all cookies set on our domain will be removed.

We will provide you with a list of cookies stored by your computer on our domain.

For security reasons, we cannot show you cookies stored by other domains. You can view these in the security settings of your browser.

These cookies collect information that - sometimes in aggregate form - helps us understand how our website is used and how effective our marketing measures are. We can also use the knowledge gained from these cookies to adapt our applications to improve your user experience on our website.

If you do not want us to track your visit to our site, you can block this in your browser here:

For more information about our cookies and privacy settings, please visit our privacy page.

Datenschutz