Modular spreader frames from OX & RUD Lifting Solutions

The modular spreader frame from OX & RUD Lifting Solutions achieves spans of up to 24 x 24 m thanks to variable strut lengths and is suitable for loads of up to 250 t. Modular frames with a capacity of 9 to 170 t are also in stock and can therefore be delivered at short notice (subject to prior sale). Due to the design of the corner units, the frames can be used as a square or a rectangle.

The same applies here: the frame struts may consist of a maximum of six struts per side, with the longest component being placed in the middle of the configuration. The more struts you use, the greater your flexibility in being able to react to intermediate lengths during subsequent lifting operations.

Modular spreader frames with four attachment points are particularly suitable for use where working heights are limited.

Using four matching corner units, struts (which may already be present) can be assembled to form a 4-point spreader frame. Such a lifting solution is ideal if you need more than two lifting points and the working height is limited, i.e. if a cascade arrangement of normal standard spreaders is not an option.

Each component is provided with a nameplate so that it can be assigned quickly and safely. The load capacities at different lengths are detailed in the user instructions.

Advantages of a modular spreader frame

There are numerous advantages to using modular spreader frames. We have therefore briefly summarized the main arguments for you here:

Properties of a modular spreader frame

Mild steel and steel with a high elastic limit are used to manufacture the spreader frames. Delivery including a 3.1 Material certificate is possible (must be confirmed when ordering).

Finish:

- The primer of the products consists of sandblasting Sa 2.5 in accordance with ISO 8501-1.

- This is followed by a layer of epoxy zinc phosphate primer with a thickness of 50 µm.

- The finish is completed with two layers of polyurethane enamel paint RAL 2004.

- Painting in your company color is possible upon request, but with longer delivery times.

- Further options upon request.

Note:

Attention! The modular frame spreader beams do not have DNV-GL type approval.

Information about the sling angle

The sling angle influences the required sling length. If you are unsure, please contact us.

Important notes:

- Slings and shackles must never come into direct contact with the spreader frame. Be sure to maintain a sufficient distance between them!

- The sling angle of the lower slings must not exceed -6°/+6° at any time, even with the spreader frame!

Our all-round carefree service for you:

We would be happy to provide you with a complete offer for the modular spreader beams. Just ask us about suitable shackles and slings!

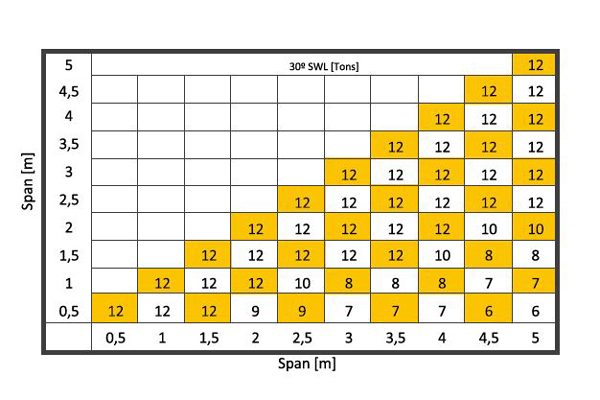

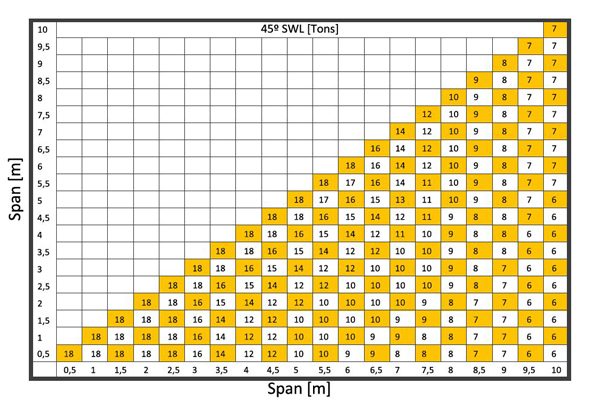

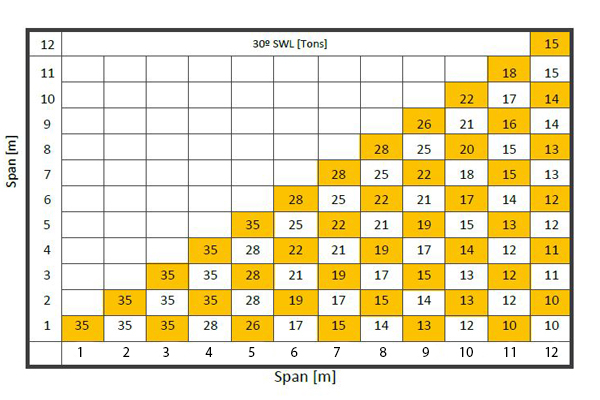

Spreader frame delivery program

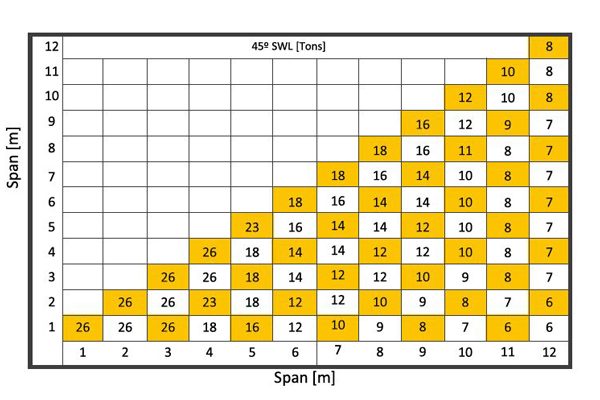

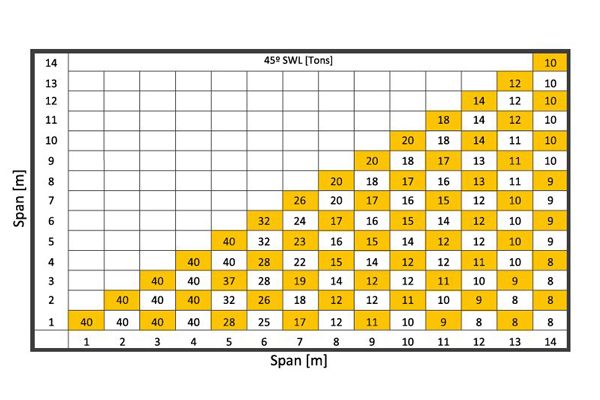

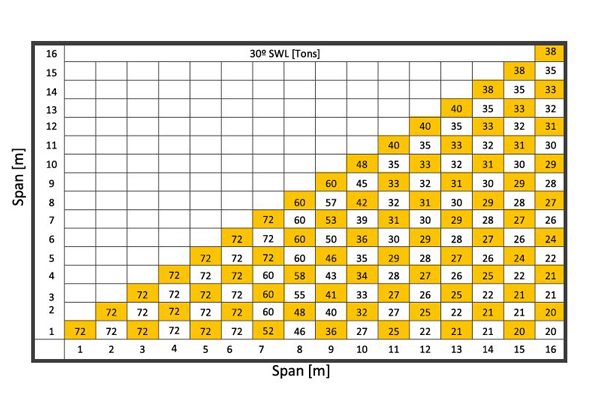

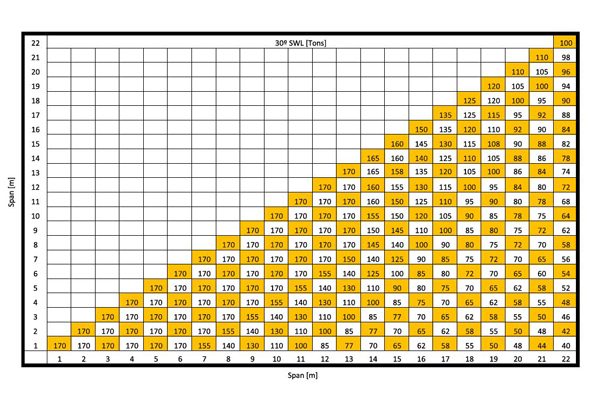

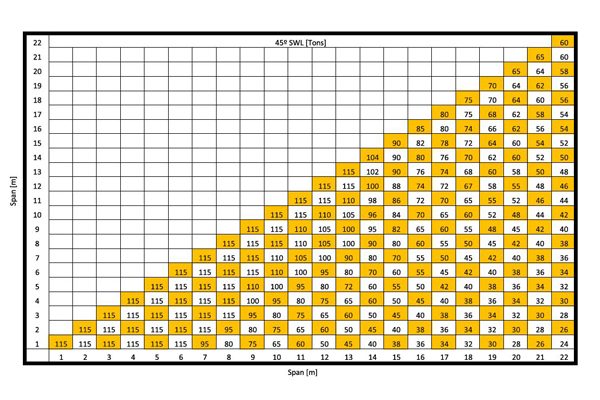

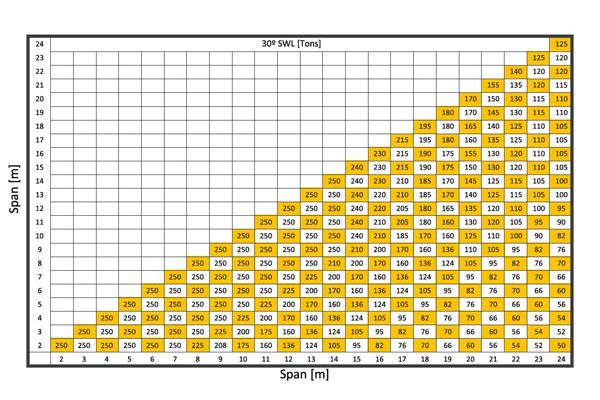

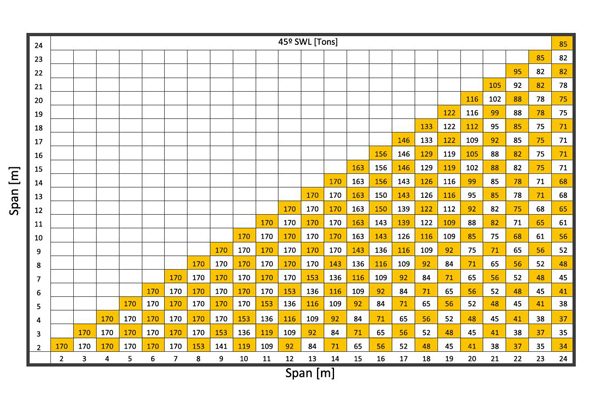

You can easily find out which modular spreader frame fits from the load capacity and span table. Finding the right spreader beam model for a regular lifting process is very easy: first select the required load capacity and then the required span. You will now receive the variant from the spreader frame delivery program that best suits your current project.

Please be sure to observe the capacity limits. If the weight to be transported is at a limit, it is advisable to select the higher category and therefore the more stable model. If the nominal load capacity is exceeded, the safety of the traverse is no longer guaranteed.

We would also be happy to advise you on more complicated projects. These are, for example:

- lifting goods with a shifted center of gravity

- Loads with more than four lifting points

CU-OX-SB-09 / Sling angle 30°

CU-OX-SB-09 / Sling angle 45°

CU-OX-SB-17 / Sling angle 30°

CU-OX-SB-17 / Sling angle 45°

CU-OX-SB-24 / Sling angle 30°

CU-OX-SB-24 / Sling angle 45°

CU-OX-SB-34 / Sling angle 30°

CU-OX-SB-34 / Sling angle 45°

CU-OX-SB-50 / Sling angle 30°

CU-OX-SB-50 / Sling angle 45°

CU-OX-SB-70 / Sling angle 30°

CU-OX-SB-70 / Sling angle 45°

CU-OX-SB-110 / Sling angle 30°

CU-OX-SB-110 / Sling angle 45°

CU-OX-SB-170 / Sling angle 30°

CU-OX-SB-170 / Sling angle 45°